I never thought of the copacker idea. The problem with that is I have to find someone with a smoker. I don't think I have a chance at Rib Crib but There is one meat store in town, but I don't know if he smokes meats. Maybe I could pay him in pigs, I'll certainly have enough of them running around.

It's worth a shot. I could get six pigs done and do 12 hams and 12 sides, cure them in meat lugs, hang them in his walk in for a couple of weeks then smoke n. slice them up. I'd just have to be careful that no one steals my ham and tries to 'hock' it.

Yes guys, we're just getting started and just put the website up as a place holder.

The pay as they grow program is designed to help a family work a whole (or half) pig into their grocery budget. They put a down payment about six months out from slaughter and then a monthly payment which estimates the hanging weight of the animal. We balance at slaughter, as I bring the animal to the packing house and they pay for the customized butchering. I'm learning fast to take a deposit on everything. I had one piglet customer back out. But I've still got six sold.

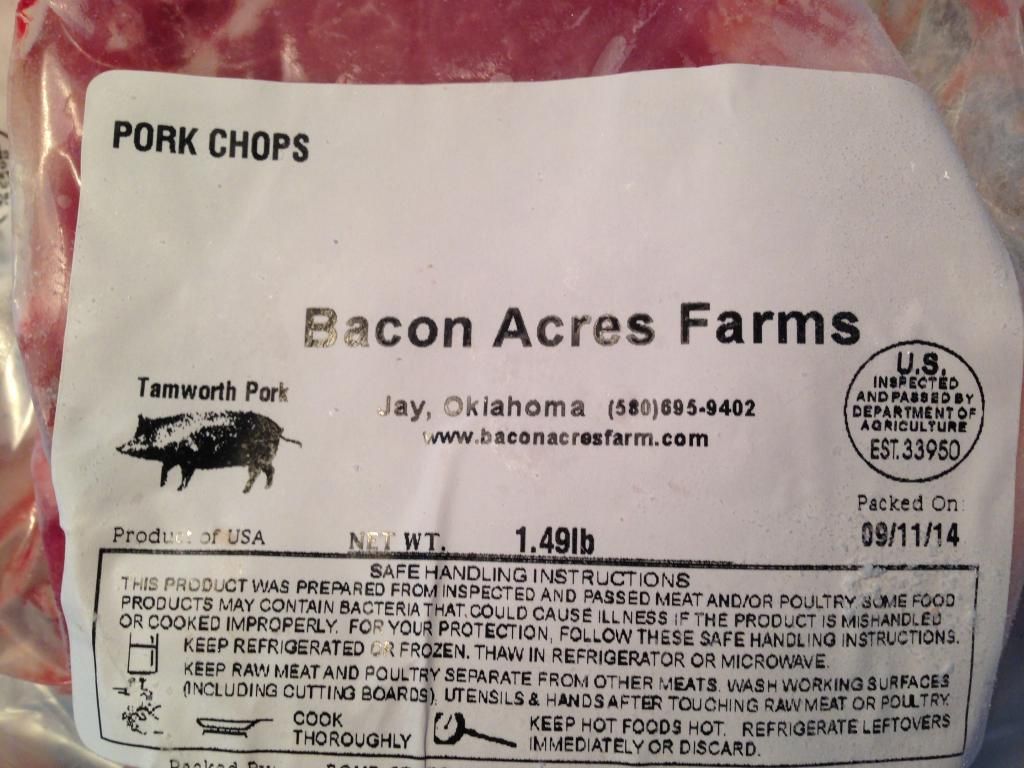

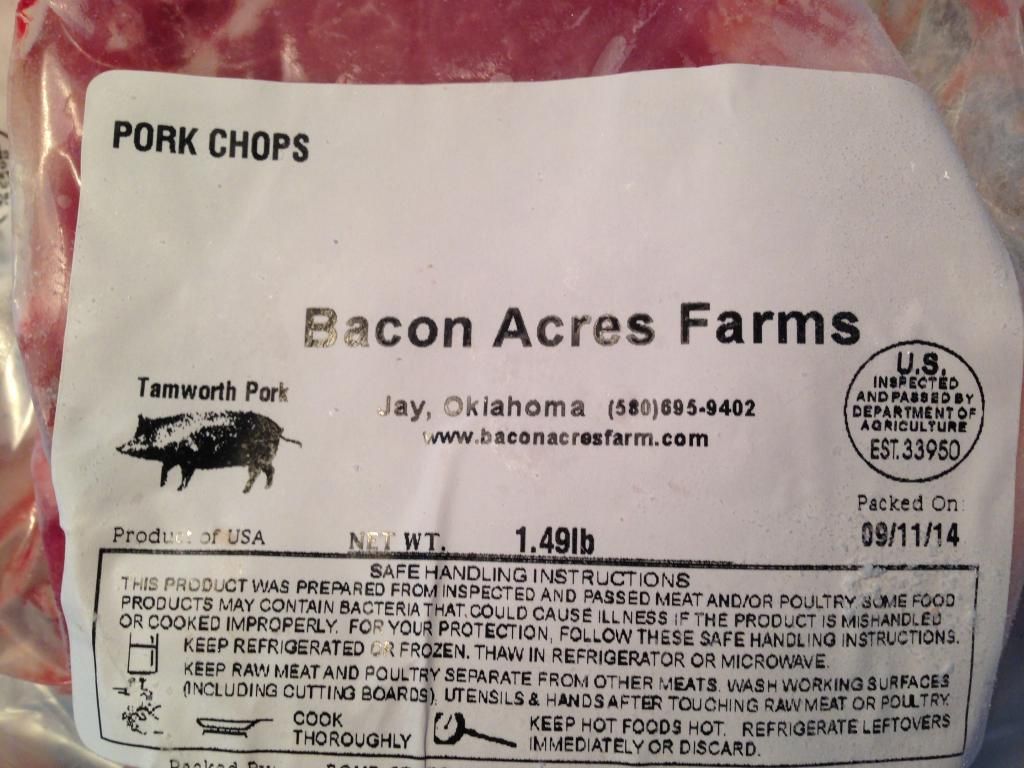

This marketing is what's killing me. We've got our USDA label back and a freezer full of pork USDA Certified Tamworth Pork that we need to sell, but a little clueless on how to do it. Currently it's just word of mouth now and craigslist stuff and I'm afraid I'll be hurt by substandard bacon this go around. I've decided not to sell the deli ham and will just take the loss on it. The bright side is that, in the pig business, I can always eat my mistakes.

If you guys want more info, see my facebook page (link is good on the website), as I'm more active on there.

By the way, I don't know if you guys saw Fast Eddy's post today (on FB I think) about the charcuterie class, but I'm going to hit it up next time it gets back to KC. Sounds like a winner.