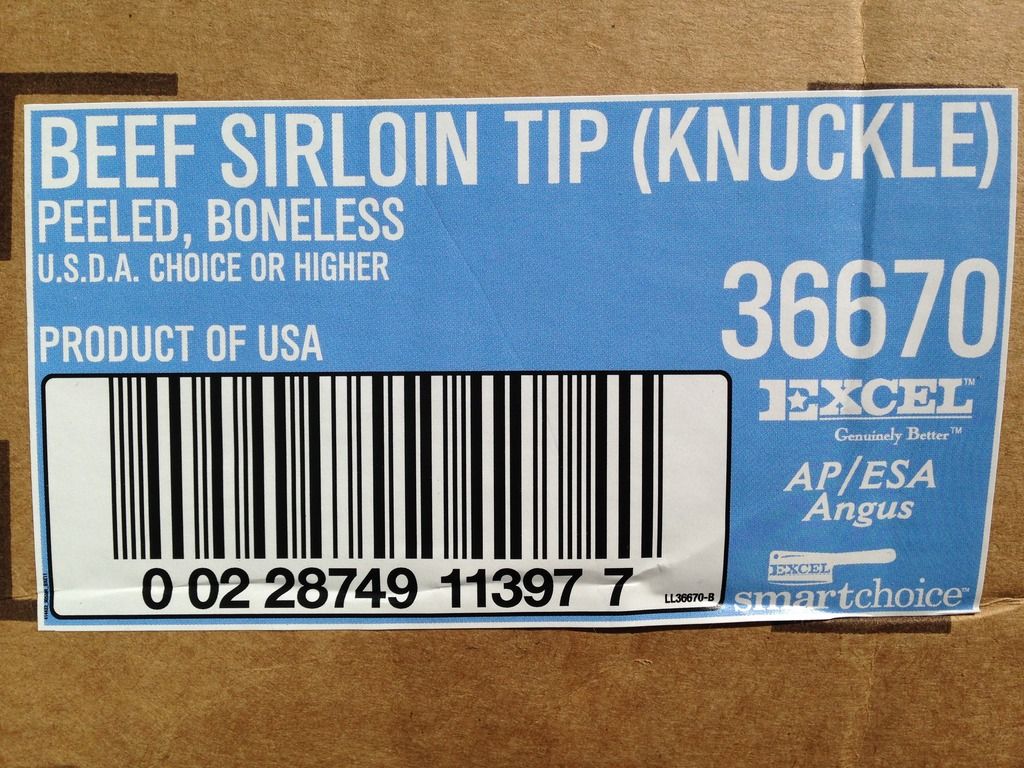

I Stopped by Sams Club and picked up a case of Sirloin Tip (Peeled Knuckle) for 3.29/pp. The case weighed 62 pounds. The other choices they had were eye of round, top round and bottom round, each slightly more per pound. I stuck with what I knew, the knuckles.

The case of knuckles contained six roasts. I rinsed the roast and removed a little of the ‘not-too stubborn’ silver skin and any visible fat. Since I was going to slice them, I didn’t see silver skin as a real problem. All toll, trim at this point resulted in less than a pound of waste. I put the six roasts unwrapped in my meat fridge suspended over a wire rack to allow them to dry for a couple of days.

Next, into the freezer for about three hours to get them a little slushy, yet not completely frozen, while I set up my processing station.

The goal here was to singlehandly slice and season these six roast. This was a perfect job for my new Berkel 827A 12-inch meat slicer. The slices came out perfect. My goal was around 1/8th inch thin and as big-a-pieces I could manage. Along the way, I had a few more fat chunks, and the last small piece from each roast remaining. These pieces, totaling 4.5 pounds and packaged and frozen for this winter’s sausage. The slicing was easier than I had dreamed. The blade just wisk right thru the raw meat and resulted in perfectly thin slices. Honestly, I think I could have sliced it without par-freezing it, but It would have been messier.

Last year, I had purchased two 5-pound bulk boxes of high mountain jerky seasoning and a seven-pound box of cure, so I had some remaining. My two flavors were Mandarin teriyaki and Low Sodium Hunter’s blend. High Mountain seasoning can be purchased in bulk at a significant discount and at even a greater discount if you own a business or farm-store like ours. At the wholesale/bulk pricing, it cost about 15-cents to season/cure a pound of raw meat, totaling less than $9.00 for both of my two 30-pound batches. Retail is round 55-cents per pound of raw meat for jerky cure/seasoning.

I mixed up 6.0 ounces of seasoning and 8.4 ounces of cure for each batch. I put the cure with the respective seasoning in a 5-pound plastic rib-rub jar and shook to mix well. In retrospect, I should have put the seasoning/cure mix to the coffee grinder to even out the grains and freshen up the spices.

Applying the Seasoning to the meat was a bit tricky working alone. After I sliced each roast, I would lay all the slices down in a meat lug one layer at a time and season the top side of them. I figured that since the meat was so thin, it would penetrate. The instructions on the High Mountain Jerky cure states that it penetrates at the rate of ¼ inch per 24 hours.

Surprisingly the slicing and seasoning only took about an hour to complete all six roast and to have them back in the refrigerator.

Prior to putting the sliced meat back in the refrigerator, I weighted everything and including the 1.75 pounds of added spice/cure weight, I had 53 pounds of product. My guess is the delta of weight was from the moisture on the roast and was removed during the long uncovered refrigeration. Oh well, jerky has to dry – Right?

After a couple of days, I began smoking the jerky. My goal was 178 degrees until done using pecan pellets on the FEC 100. Sirloin tip, like many jerky cuts is not a perfect meat. It does have a couple of veins of fat running thru in some places. Using the FEC 100 with the 7 rack system, I tried to put 28 pieces of Jerky in each load, (4 pieces on each rack). Keep in mind that these pieces are whole cross sections of an entire knuckle roast so they take up quite a bit of real estate on the racks.

I find it much easier to smoke it all and then nip off the undesirable portions of fat and gristle with scissors after it is done. My first two loads averaged seven pounds each raw. After the 5.5 hr smoke, they averaged about 2.5 pounds finished indicating a 65 percent moisture loss while in the smoker. 8 loads total spread over five days.

The jerky was amazing: Both flavors. I took some of the Mandarin Teriyaki to church and shared it with my Sunday School Class and they loved it. With such a long process it is hard to say exactly how much jerky I finished, as much was eaten and given away prior to it all getting finished, with the yield factor, I processed just under of 20 pounds of finished jerky. Lots will be eaten, some will be sold and some will be traded for this winter’s straw.

Finished Jerky

Slices displayed on paper towel on 2x4’ folding table

Cost/Yield breakdown:

Meat: Sirloin Tip @ 3.29 pp. Case of 62 Lbs came to 213.67 with tax or 3.44/pp raw and untrimmed.

Seasoning: Hi Mountain Bulk cure. Used as prescribed, but used a little extra seasoning, but remained as per directions on the cure, came to about .20/pp for the 53 pounds of meat remaining after trim. $10.60 seasoning cost.

Pellets: Ran the FEC 100 for six hours per load for 8 loads: 48 hours at ½ pound of pellets per hour at .20/pp (BBQ delight bulk). Pellet cost: 4.80s

Total Cost for cook: 213.27 (subtracting the cost of the 4.5 Lbs of trim I set aside for sausage)

Yield is hard to figure; however, on the test loads I did, I received about 2.5 pounds of finished jerky out of the FEC 100 for every 7 pounds I put in. Considering everything (meat cost, trim, seasonings, pellets) except packaging, and allowing for the 4.5 Lbs of trim I put up for myself, the cost comes out to just over 11.00 per pound finished.

Here is a picture of a standard meat lug containing exactly the 2.5 pounds of finished jerky I removed from the FEC 100 on one of my test loads. This was one of the 8 loads I did. The pieces are huge, most the size of an 8’’ Dixie plate. Later in the process, I started cutting the pieces in half and thirds at the half-way-thru point while smoking, just to save a little time.