Greetings fellow CookShackers. I know the SM066 has a hold feature BUT it is only for six hours, and I know that I can set the temp to 145 or 150 and walk away as well. I have been searching far and wide on the internet for holding oven ideas without dropping 4500 bucks on a real holding oven.

My plan is to hold briskets at 150 degrees for at least 24 hours prior to serving. I am doing brisket over the Memorial Day weekend.

In the spirit of American exceptionalism, I discovered a Canadian beat me to the punch on this. Not only did he turn a cooler into a holding oven, but he also turned an old chest freezer into one as well. Here is the link: https://youtu.be/-6ocRbEU7io

He did not give any specifics. He just drilled a hole and shoved in the Sous Vide.

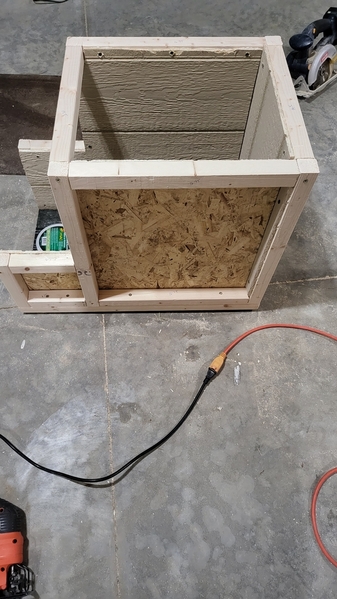

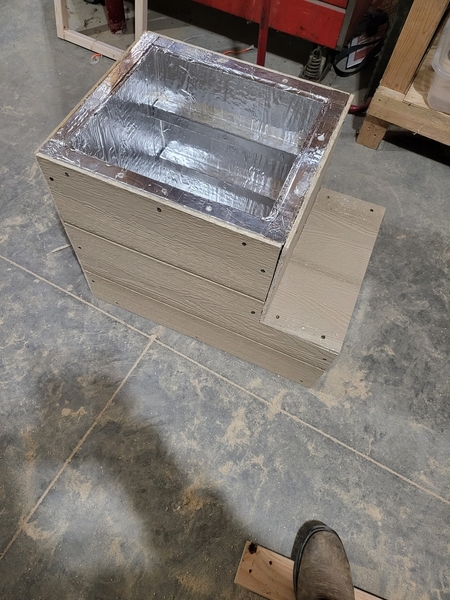

Here is my take on this.

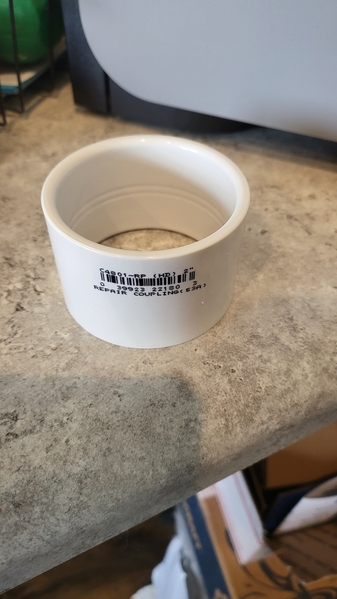

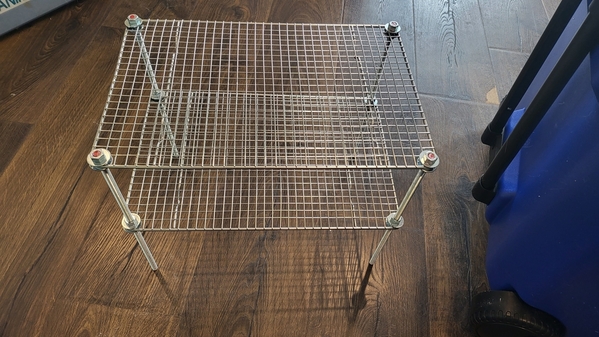

Parts: JB Weld, Marine adhesive, two – (2) inch repair couplings, one – 1.5-inch pvc cleanout with plug (optional), four – 12-inch threaded rods, 16 flat washers, 16 nuts, 2 cooling racks that fit your cooler, and 2.75-inch hole saw.

I drilled a hole in the cooler at an angle so the Sous Vide heater would somewhat vertical. JB Weld the two repair couplings together and insert them into the hole. Use the marine adhesive to seal the hole and glue the couplings into place.

The rods, washers, and nuts are for holding the rack up and keeping it together.

I am not providing any measurements for hole location or rack set up as it is cooler dependent. The cleanout plug can be insert into the coupling if you want to use the cooler as a cooler.

It's not pretty but see the pics below. It was more difficult than I though to drill a vertical hole in the side of a cooler.